- +91 9605 771 555, +91 7510 331 777

- jcetadmissions@nehrucolleges.com

jcetncerc@gmail.com

Mechanical Engineering

About

The Department of Mechanical Engineering was started in the year 2008. The department offers B. Tech. program in Mechanical Engineering. Mechanical Engineering department has a team of highly qualified and experienced faculty, well developed infra structure and lab facilities. At present, the department intake capacity is 60 students per year at the B. Tech. level. The department helps the students to develop their overall personality and make them worthy to compete and work at global level. The department has evolved a comprehensive student-centric learning approach, designed to add significant value to the learner's understanding in an integrated manner through workshops, lab sessions, assignments, training, seminars, projects and independent study.

A degree in Mechanical Engineering is ideal preparation for starting a career in the Automotive, Aerospace, Process, Medical and Marine industries or other areas such as accountancy. Many of our graduates go on to take their careers that make an important contribution to society in terms of wealth generation, safety and environmental sustainability. Apart from carrying out practical classes as per academic curriculum, workshop caters to needs of different departments of the Institute in terms of executing works of their B.Tech. The department also welcomes students from other departments of the institute as a gesture of support to their time-to-time academic needs. The students are well placed in leading industries as well as in the higher research level institutions of national and international recognition.

Dr. Shine K

HOD & Professor

HOD’S Desk

Mechanical Engineers play a significant role in the design and manufacturing of all of the products and systems essential to everyday modern life. Mechanical engineers create solutions and troubleshoot problems, playing a key role in the design and implementation of systems parts in many industries. They enjoy solving problems using powerful mathematical, scientific, and analytic skills.

Mechanical engineers can be involved in managing people, projects, and resources, as well as in developing and using new materials and technologies. It is predicted that an increasing number of engineers will have interdisciplinary training courses, more often working in multidisciplinary teams.

Our department is mainly aimed to provide the useful knowledge to the students in developing innovative thoughts for future India.We have a team of dedicated and experienced faculty, driving the department towards excellence in teaching. We believe in holistic development of students and aim at identifying the hidden skills, developing the personality and inculcating human values to mold our students into technically-qualified professionals ready to face the competitive world.

| SI NO | NAME | DESIGNATION |

|---|---|---|

| Teaching Faculty | ||

| 01 | Dr. Shine K | HOD & Professor |

| 02 | Mr. Ragesh P.R | Assistant Professor |

| 03 | Mr. Anoop Vasudevan K | Assistant Professor |

| 04 | Mr. Ajith Mohan M | Assistant Professor |

| 05 | Mr. Krishnaprasad C N | Assistant Professor |

| 06 | Mr. Sajeesh N | Assistant Professor |

| 07 | Mr. Sadanandan R | Assistant Professor |

| 08 | Mr.Deepu T | Assistant Professor |

| Technical Faculty | ||

| 01 | Mr. Velayudhan K.K | W/S Incharge |

| 02 | Mr. N. Andavan | W/S Instructor |

| 03 | Mr. Arun P S | Lab Instructor |

| 04 | Mr. Suresh Babu.S | Lab Instructor |

| 05 | Mr. Sandeep K | Lab Assistant |

Facilities

To be a good mechanical engineer one needs to b e an expert in what he does. The Mechanical Engineering Department at JCET provides the upcoming engineers with the most equipped laboratories covering all experiments of importance. The fully equipped laboratories are considered to the best among the engineering colleges all over Kerala. The laboratories are equipped with the most modern instruments, machines and computers. The Practice laboratories for different semesters are listed below.

Thermal Engineering Laboratory

The first thing for a student when he hear about mechanical engineering are the vehicles which they see in the world. Even though its a wrong conception since it is more in concern about automobile engineering, the mechanical engineering students have to study about Internal Combustion Engines, the heart of automobiles. In IC engines they could study about various performance test on engines. This laboratory helps the student to learn in more about the automobile components and also about the performance parameters of engines. The experiments are conducted in 2 stroke and 4 stroke engines which were actually in use.

Machine Shop

Machine Tools consists of various equipment that manufacture products according to the design provided. The Mechanical Engineering students as a part of the syllabus are given a chance to study about different machine tools like lathe, shaper, slotter. In Machine Tool laboratory students are expected to manufacture a product on the basis of a design provided that covers operations like centering. turning, thread cutting. The student need to apply his innovative skill to develop the work piece given to a suitable output. The lab also provides them a chance to study the machine in closer and to develop the in-borne talent in them.

In this laboratory which is a continuation of the machine tool laboratory are equipped with machines like shaper, slotter. The students are also given the chance for a hands on experience in part programming in Computer Numerical Control machines. the most modern machine provided at JCET help the students to know about the various commands included in the machine. The industries are now equipped with CNC’s and hence a practice in CNC help the students to grab knowledge by creating a part programme for a desired product.

Cad / Cam Laboratory

CAD/ CAM Laboratory offers the students to grab knowledge in the design softwares that are used in the engineering design field. The world as it progress finds newer technologies to accomplish the task assigned at a faster pace. The engineers need to be in touch with the design softwares as drawing is a tool for an engineer to communicate. AUTOCAD providing the root to the design softwares, various design softwares like Pro E, Solid Works,SolidEdge,CATIA have been developed. Along with that various analysis softwares like NISA, ANSYS, ABAQUS are also used in the industry. The students are given a chance to get in touch with software through CAD/CAM Laboratory.

Metrology And Instrumentation Laboratory

The lab is equipped with various measuring and control equipment like Pressure Gauge, Temperature Measuring Devices, Torque Sensor, Displacement Measuring Device, Various Strain gauges, Speed measuring Device, stroboscope, Force measuring Device, etc

Fluid Machinery Laboratory

The Hydraulic Machines Laboratory provide the students a chance to work with turbines and pumps. The lab is equipped with the model of the commonly used turbines in power generation like Pelton Wheel, Kaplan Turbine, Francis Turbine. The laboratory is also equipped with various pumps that come across in our day to day life. The Hydraulic Machines Laboratory helps the students to clearly understand the working of pumps and turbines.

Fluid Mechanics Lab

The subject fluid mechanics is one of the core sector in the mechanical engineering field dealing with the fluid properties, type of flow, the governing equations of the behaviour of fluid . The students are given exposure to the various theory portions covered in the syllabus by the experiments arranged in the Laboratory. This well equipped laboratory consists of the experiments related to the basics of fluid mechanics and also to various experiments related to fluid flow and the measurement of discharge and velocity of flow. Students are given the best opportunity to clearly understand the concepts they were taught in Fluid Mechanics subject.

Mechanical Engineering Workshop

It is always best to start from the basics. The Basic Mechanical Workshop helps the students to get in touch with the conventional way of production in mechanical engineering. They are given a chance to have hands on experience in carpentry, smithy, fitting and foundry. The students get knowledge in the conventional methods by doing the experiments on their own.

Achievements

Students of mechanical engineering department secured Second position with cash prizes of Rs. 5000 in "NGI IDEATHON 2024" organised by Nehru group of institutions technology business incubator.

PLACEMENTS

- 20 Students got placement in the academic year 2019-2020

- 23 Students got placement in the academic year 2018-2019

- 10 Students got placement in the academic year 2020-2021

- 11 Students got placement in the academic year 2021-2022

- 21 Students got placement in the academic year 2022-2023

PAPER PRESENTATION

- Ms. Nithya A and Mr. Saurav S (students of S8 Mechanical) published a paper on “Unlocking the World of Agri Tools and Implements” PMA in June 2023.

- Five projects from 2019-2023, presented in various conferences.

FUNDED PROJECTS

AY: 2023-2024

- 5 projects applied for KTU fund approval.

- 2 projects selected for KTU Tech fest at IIT Palakkad.

OTHER ACHIEVEMENTS OF STUDENTS

- Sandeep s, Saran k, Rajeev s Nair, Sarath V S of S-7 Mechanical got selected from State level Empowering youth hackathon 2020 to National level for their innovative concept “Algae powered lamp”.

- Arjun KP & Vyshakh Baburajan of Mechanical department won First Prize in Mechtraki held as part of Tathva’16 at NIT Calicut.

- "Best Upcoming Start Up" title at the event Interface , held as part of the NIT's biggest tech fest Tathva 2018. Janiya Santh , Sachin Emmatty and Salman Salim

RESEARCH AND DEVELOPMENT

- Dr. Shine K (HoD/ME) got Guideship in APJAKTU in 2023.

- Dr. Shine K (HoD/ME) reviewed a Book Chapter Titled “On the existence of metastable microheterogeneities in metallic melts” in Current Innovations in Chemical and Material Sciences in 2024.

FACULTY PURSUING Ph.D

- Mr. Ragesh P R completed comprehensive viva as a research scholar of APJAKTU at NSS College of Engineering Palakkad.

- Mr. Vishnu Narayan got opportunity to pursue Ph.D from NIT Calicut in December 2023

- Mr. Chamind E C got opportunity to pursue Ph.D from IIT Palakkad in June 2023

- Mr. Nishanth S got opportunity to pursue Ph.D from APJAKTU at GEC Thrissur in November 2023.

FDP ORGANIZED BY DEPARTMENT OF MECHANICAL ENGINEERING

- Department of Mechanical Engineering conducted FDP on “Renewable and Green energy strategies for sustainable development” on 24-04-2023- to 28-04-2023.

- Conducted two day FDP on “Latex and Catia for Engineers” on 26/08/2022 – 27/08/2022.

- Conducted hands on workshop on CATIA-V5 on 25/03/2022 – 27/03/2022.

- On 9th December 2022, Department of Mechanical Engineering organized a Technical Talk on “INDUSTRIAL ROBOTICS AND ARTIFICIAL INTELLIGENCE”.

FDP ATTENDED BY FACULTIES

-

The following faculty members from Department of Mechanical Engineering has attended 5 day FDP on “Renewable and Green energy strategies for sustainable development” at JCET, Palakkad from 24/04/2023-28/04/2023.

- Mr. Ajith Mohan M - Mr. Sajeesh N - Mr. Krishnaprasad C N - Mr. Ragesh P R - Mr. Vishn u Narayan - Mr. Nishanth S - Mr. Krishnaprasad C N attended FDP organized by IQAC, JCET Palakkad on 03/06/2023, 01/07/2023 and 3/07/2023.

- FDP attended by Sajeesh N “ATAL FDP on Lean Six Sigma for Business Process Improvement” at SIMAT from 09/10-2023-14/10/2023.

- Mr. Krishnaprasad C N attended FDP organized by IQAC, JCET Palakkad on 30/05/2023.

OTHER ACHIEVEMENTS OF STAFF

- Dr. Shine K (HoD/ME) appointed as scrutiny member of ME362 Product Design and Development.

- Mr. Sajeesh N Appointed as University Question paper setter of ME369-Tribology S5(S,FE) Examination December 2023.

- VAC will be conducted on “Modeling and Analysis” on 10/02/2024.

INSTITUTION LEVEL DUTIES AND RESPONSIBILITIES

- IQAC Director – Dr. Shine K (HoD/ME)

- NGI TBI (K) coordinator - Dr. Shine K (HoD/ME)

- Alumni association Coordinator-Mr. Ragesh P R (AP/ME)

- Unnat Bharat Abhiyan Coordinator-Mr. Ragesh P R (AP/ME)

- Staff club President – Mr. Ragesh P R (AP/ME)

- NSS Program Officer- Mr. Ajith Mohan M (AP/ME)

Association Activities

2013-2014

Association of mechanical engineering and Association of aeronautical engineering together successfully conducted an international conference on SAFETY BY DESIGN on 13 and 14 of august 2013. Delegates from different parts of the world participated in the conference. The two days function is inaugurated by

2014-2015

Association activity of mechanical engineering department was inaugurated by Dr. A S Varadarajan, principal, Nehru college of engineering and research centre on 24 January 2015

As a part of association activity, association of mechanical engineering conducted workshop on robotics on 24 and 25 January 2015 which was very informative for the students.

2015-2016

Association activity of mechanical engineering department was inaugurated by Dr. Jacob chandapillai, Director, FCRI, Palakkad. As a part of association activity, association of mechanical engineering conducted mini project expo.

2016-2017

As a part of Association activity in the year 2016-2017 a mini project expo and moto- expo conducted in the college.

2018-2019

As a part of association activity , Successfully Completed workshop on 3 D PRINTING in November 2018. The classes was handled by Mr.vysak valsan, assistant professor department of Electronics and Communication engineering, Jawaharlal college of engineering and technology.

2019-2020

Mechanical engineering association activities for the academic year 2019-2020 inaugurated by Mr.Rajmohan G, General manager, district industries centre palakkad on 3/09/2019.

2020-2021

Association of mechanical engineering ,JCET conducted webinar series from 26/05/2020 to 29/05/2020 . The first session was on “Advancements in Refrigeration and air conditioning” handled by Mr. Jimmy Bentex, Director, C & T Engineers Pvt Ltd, Trivandrum. The second session was on “Orbitals” handled by Mr. Danish T A, Freelance trainer and counsellor, Empanelled resources with Society for Training and Development Lakshadweep. The third session was on “Role of Engineers in post COVID era” handled by Mr. Ragesh p r and Ashif maheen, Assistant Professors, Jawaharlal college of Engineering and Technology, Palakkad.

Date : 26/05/2020 to 29/05/2020

Association of mechanical engineering ,JCET conducted webinar on “What Industry needs from DME Graduates” on 9/12/2020 and the session was handled by Mr. Vinay S ,Manager-Education and Training, Conceptia Konnect.

Date : 9/12/2020

YANTRABRAHMA - 2023

KALAM KO SALAM-TREE PLANTATION DRIVE

BITS- BRINGING INDUSTRIES TO STUDENTS

WORKSHOP: HANDS ON TRAINING IN ARDUINO

ALUMNI CONNECT: Shameeh Rahman (Batch: 2013-2017) experience sharing with students.

News & Events

CONTRAPTION - NSITE

Pre NSITE Events at Jawahar Campus , Lakkidi

"Before the tech fest ignites with innovation, let's kindle the excitement with pre-tech events that set the stage for a brilliant showcase of technology sports and creativity."

Nehru Group of Institutions Kerala is here with the most awaited event A NSITE 2K23 (NEHRU SCIENCE INNOVATION & TECHNOLOGY EXPO) by opening its doors to all of you.

Mark the Date - 20,21 November 2023

For more updates,

Visit :www.nsite.co.in

MECH CORNER

Pre NSITE Events at Jawahar Campus , Lakkidi

"Before the tech fest ignites with innovation, let's kindle the excitement with pre-tech events that set the stage for a brilliant showcase of technology sports and creativity."

Nehru Group of Institutions Kerala is here with the most awaited event A NSITE 2K23 (NEHRU SCIENCE INNOVATION & TECHNOLOGY EXPO) by opening its doors to all of you.

Mark the Date - 20,21 November 2023

For more updates,

Visit :www.nsite.co.in

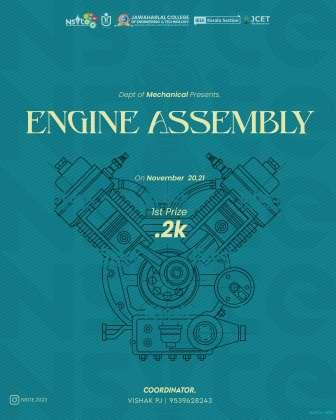

ENGINE ASSEMBLY

Pre NSITE Events at Jawahar Campus , Lakkidi

"Before the tech fest ignites with innovation, let's kindle the excitement with pre-tech events that set the stage for a brilliant showcase of technology sports and creativity."

Nehru Group of Institutions Kerala is here with the most awaited event A NSITE 2K23 (NEHRU SCIENCE INNOVATION & TECHNOLOGY EXPO) by opening its doors to all of you.

Mark the Date - 20,21 November 2023

For more updates,

Visit :www.nsite.co.in

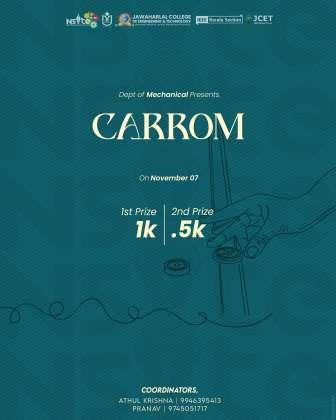

CARROM

Pre NSITE Events at Jawahar Campus , Lakkidi

"Before the tech fest ignites with innovation, let's kindle the excitement with pre-tech events that set the stage for a brilliant showcase of technology sports and creativity."

Nehru Group of Institutions Kerala is here with the most awaited event A NSITE 2K23 (NEHRU SCIENCE INNOVATION & TECHNOLOGY EXPO) by opening its doors to all of you.

Mark the Date - 20,21 November 2023

For more updates,

Visit :www.nsite.co.in

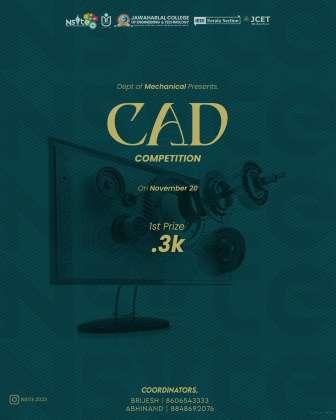

CAD COMPETITION

Pre NSITE Events at Jawahar Campus , Lakkidi

"Before the tech fest ignites with innovation, let's kindle the excitement with pre-tech events that set the stage for a brilliant showcase of technology sports and creativity."

Nehru Group of Institutions Kerala is here with the most awaited event A NSITE 2K23 (NEHRU SCIENCE INNOVATION & TECHNOLOGY EXPO) by opening its doors to all of you.

Mark the Date - 20,21 November 2023

For more updates,

Visit :www.nsite.co.in

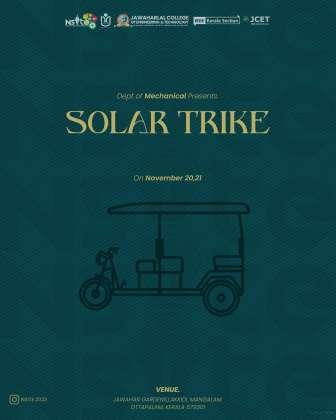

SOLAR TRIKE

Pre NSITE Events at Jawahar Campus , Lakkidi

"Before the tech fest ignites with innovation, let's kindle the excitement with pre-tech events that set the stage for a brilliant showcase of technology sports and creativity."

Nehru Group of Institutions Kerala is here with the most awaited event A NSITE 2K23 (NEHRU SCIENCE INNOVATION & TECHNOLOGY EXPO) by opening its doors to all of you.

Mark the Date - 20,21 November 2023

For more updates,

Visit :www.nsite.co.in

VOLLEYBALL

Pre NSITE Events at Jawahar Campus , Lakkidi

"Before the tech fest ignites with innovation, let's kindle the excitement with pre-tech events that set the stage for a brilliant showcase of technology sports and creativity."

Nehru Group of Institutions Kerala is here with the most awaited event A NSITE 2K23 (NEHRU SCIENCE INNOVATION & TECHNOLOGY EXPO) by opening its doors to all of you.

Mark the Date - 20,21 November 2023

For more updates,

Visit :www.nsite.co.in

YANTRABRAHMA - 2023

Department of Mechanical Engineering: Inaugural Session of YANTRABRAHMA - 2023 was inaugurated by the chief Guest , Vishnu Vijay Kumar,Senior Researcher at IIT Madras on 26th October 2023

KALAM KO SALAM-TREE PLANTATION DRIVE

KALAM KO SALAM-TREE PLANTATION DRIVE

WORKSHOP: HANDS ON TRAINING IN ARDUINO

HANDS ON TRAINING IN ARDUINO organised by Yantra Brahma- Mechanical Engineering Association on 30th September 2023

BITS- BRINGING INDUSTRIES TO STUDENTS

Department of Mechanical Engineering organized a programme on Introduction to Drone Technology -As a part of BITS-Bringing Instrutries To Students on 18th September 2023

FDP in RENEWABLE & GREEN ENERGY STRATEGIES FOR SUSTAINABLE DEVELOPMENT

This FDP is designed to give exposure to the latest green energy strategies and engineering practices adopted for the sustainable development of the society and the nation. A comprehensive understanding of the latest renewable energy technologies, energy efficient processes, energy conservation measures and environment-friendly design, etc. are needed to apply and implement different strategies for ensuring sustainability. Upon completion, participants will be able to train their students on energy efficient and eco-friendly engineering practices and renewable energy harnessing methods.

For More Details, https://jawaharlalcolleges.com/blog/?p=2411

PLACED STUDENT 2020-2024 BATCH

Congratulations to all the students who got placed in various reputed companies

PLACED STUDENT 2020-2024 BATCH

Congratulations to all the students who got placed in various reputed companies

Vision

- To Bring in Holistic Development and Achieve Global Level Excellence in Imparting Academic and Industry Oriented Knowledge and Skills to Mechanical Engineering Scholars to Keep them in Demand by Major Players in Engineering Field World Over.

Mission

- To Provide Infrastructure Facilities, Teaching Aids, and Ambience to Students to Enable them Acquiring State-of-the-Art Technical Know-How Through Competent and Committed Faculty.

- To Equip Them with Entrepreneurial Expertise Through Industry Interaction for Making Them Employers Rather Than Employees.

- To Mould the Students as True Citizens with Necessary Coaching and Equipping with Tools for Meeting Societal Needs and Enabling them to Become Efficient and Capable Mechanical Engineers.

Program Educational Objectives (PEOs)

- The Graduates will Apply their Knowledge in Mechanical Engineering and Proficiency in Using Various Software to Design, Manufacture, Test, Analyze and Ensure Quality Aspects, Inculcating Lifelong Learning.

- The Graduates will Acquire Various Important Entrepreneurial Qualities as Part of Self-Development Qualities such as Leadership Team Building Communication Problem Solving, Decision Making, Software, and Creative Skills Leading to Societal Contributions and Overall Career Development.

- The Graduates will be Aware of their Role with Respect to their Responsibilities and Services Linked with Employers, Society, Peers, and Ethical Values Throughout their Careers.

Program Specific Outcomes (PSOs)

The Students will have

- Proficiency in Conceiving Design Ideas, Developing Proto-Models, Fabrication, Testing, and Analysis Through Software Tools and thus Achieving Capabilities Needed for an Efficient Mechanical Engineer.

- Capability Based on Knowledge, Skill, Aptitude, and Attitude to Comprehend Engineering Aspects of Various Machine Elements, Production Processes, and Various Systems.

PROGRAM OUTCOMES(POs)

Engineering Graduates will be able to:

- Engineering knowledge: Apply the knowledge of mathematics, science, engineering fundamentals, and an engineering specialization to the solution of complex engineering problems.

- Problem analysis: Identify, formulate, review research literature, and analyze complex engineering problems reaching substantiated conclusions using first principles of mathematics, natural sciences, and engineering sciences.

- Design/development of solutions: Design solutions for complex engineering problems and design system components or processes that meet the specified needs with appropriate consideration for the public health and safety, and the cultural, societal, and environmental considerations.

- Conduct investigations of complex problems: Use research-based knowledge and research methods including design of experiments, analysis and interpretation of data, and synthesis of the information to provide valid conclusions.

- Modern tool usage: Create, select, and apply appropriate techniques, resources, and modern engineering and IT tools including prediction and modeling to complex engineering activities with an understanding of the limitations.

- The engineer and society: Apply reasoning informed by the contextual knowledge to assess societal, health, safety, legal and cultural issues and the consequent responsibilities relevant to the professional engineering practice.

- Environment and sustainability: Understand the impact of the professional engineering solutions in societal and environmental contexts, and demonstrate the knowledge of, and need for sustainable development.

- Ethics: Apply ethical principles and commit to professional ethics and responsibilities and norms of the engineering practice.

- Individual and team work: Function effectively as an individual, and as a member or leader in diverse teams, and in multidisciplinary settings.

- Communication: Communicate effectively on complex engineering activities with the engineering community and with society at large, such as, being able to comprehend and write effective reports and design documentation, make effective presentations, and give and receive clear instructions.

- Project management and finance: Demonstrate knowledge and understanding of the engineering and management principles and apply these to one’s own work, as a member and leader in a team, to manage projects and in multidisciplinary environments.

- Life-long learning: Recognize the need for, and have the preparation and ability to engage in independent and life-long learning in the broadest context of technological change.

SEMESTER 1 (KTU 2019 Scheme)

|

Sl. No |

Subject Code |

Name of Subject |

Name of Book |

Name of Reference Book |

|

1 |

MAT 102 |

Vector calculus, Differential Equations and Transformations |

H Anton,I Biven,S Davis,Calculus,Wiley 10th edition ,2015.2) Erwin Kreyszig AdvancedEngineering Mathematics , |

|

|

2 |

CYT 100 |

Engineering Chemistry |

Dr Muhammed Arif M,Smt Kavitha P Nair,Dr Annette Fernandence |

|

|

3 |

EST 110 |

Engineering Graphics |

Engineering Graphics by P. I. Varghese published by V I P Publishers |

|

|

4 |

EST 130 A |

Basics of Electrical Engineering |

Basic Electrical Engineering by T S Rejin The New Media space publication |

1. Basic Electrical Engg by V K Mehta and Rohit Mehta S. Chand Publication |

|

|

EST 120B |

Basics of Mechanical Engineering |

Benjamin,J.,Basic Mechanical Engineering,Pentex Books,9th Edition,2018 |

Balachandran, P.Basic Mechanical Engineering,Owl Books |

|

5 |

HUN 102 |

Professional Communication |

Professional English,M A Ashraf Rizvi,Effective Technical Communication,Tata McGraw-Hill Publishers |

|

|

6 |

EST 102 |

Programming in C |

Asok N Kamthane, Pearson,Programming in C |

Rajaraman V, PHI, Computer Basics and Programming in C |

SEMESTER 2 (KTU 2019 Scheme)

|

Sl. No |

Subject Code |

Name of Subject |

Name of Text Book |

Name of Reference Book |

|

1 |

MAT101 |

Linear Algera and Calculus |

H Anton,I Biven,S Davis,Calculus,Wiley 10th edition ,2015.2) Erwin Kreyszig AdvancedEngineering Mathematics ,10th edition John Wily & sons 2016 |

|

|

2 |

PHT 110 |

Engineering Physics |

Dr K P Varkey, Prof V S Nithyadas, Prof A K Haridas, Prof A Athmajan |

|

|

3 |

EST100 |

Engineering Mechanics |

Engineering Mechanics, J Benjamin, 2019 Revised Edition |

Timoshenko and Young, Engineering Mechanics, McGraw Hill Publishers |

|

4 |

EST 120 A |

Basics of Civil Engineering |

Rangwala, S. C., Essentials of Civil Engineering, Charotar Publishing House |

Shibu Nalapat, Basic Civil Engineering, Nalapat Publishers |

|

5 |

EST 130 B |

Basics of Electronics Engineering |

ChinmoySaha, Arindham Halder and Debarati Ganguly, Basic Electronics - Principles and Applications, Cambridge University Press, 2018. |

Anant Agarwal, Jeffrey Lang, Foundations of Analog and Digital Electronic Circuits, Morgan Kaufmann Publishers, 2005. |

|

6 |

HUN 01 |

Life Skills |

Life Skills of Engineers,Ramesh.S,Vishnu R G,Ridhaima Publication,Trivandram |

|

SEMESTER 3 (KTU 2019 Scheme)

|

Sl. No |

Subject Code |

Name of Subject |

Name of Book |

Name of Refernce Book |

|

1 |

MAT 201 |

PARTIAL DIFFERENTIAL EQUATION AND COMPLEX ANALYSIS |

B.S Grewal ,Higher Engineering Mathematics,Khanna Publishers,44th Edition,2018 |

|

|

2 |

MET201 |

MECHANICS OF SOLIDS |

R. K. Bansal, A Text book of Strength of Materials, Laxmi Publications (P) Ltd, New Delhi |

Ramamrutham and R. Narayanan, Strength of Materials, Dhanpat Rai Publishing Co (P) Ltd. |

|

3 |

MET203 |

MECHANICS OF FLUIDS |

Bansal R. K., A Textbook of Fluid Mechanics and Hydraulic Machines, Laxmi Publications, 2010. |

Modi P. N. and S. M. Seth, Hydraulics & Fluid Mechanics, S.B.H Publishers, New Delhi, 2002. |

|

4 |

MET205 |

METALLURGY & MATERIAL SCIENCE |

Callister William. D., Material Science and Engineering, John Wiley, 2014 |

Avner H Sidney, Introduction to Physical Metallurgy, Tata McGraw Hill,2009 |

|

5 |

MCN 201 |

SUSTAINABLE ENGINEERING |

Allen, D. T. and Shonnard, D. R., Sustainability Engineering: Concepts, Design and Case Studies, Prentice Hall |

Bradley. A.S; Adebayo,A.O., Maria, P. Engineering applications in sustainable design and development, Cengage learning |

|

6 |

EST 200 |

DESIGN AND ENGINEERING |

Voland, G., Engineering by Design, Pearson India 2014, Second Edition, ISBN 9332535051 |

Philip Kosky, Robert Balmer, William Keat, George Wise, Exploring Engineering, Fourth Edition: An Introduction to Engineering and Design, Academic Press 2015, 4th Edition, ISBN: 9780128012420. |

|

7 |

MEL201 |

COMPUTER AIDED MACHINE DRAWING |

N. D. Bhatt and V.M. Panchal, Machine Drawing, Charotar Publishing House. |

P I Varghese and K C John, Machine Drawing, VIP Publishers |

SEMESTER 4 (KTU 2019 Scheme)

|

Sl. No |

Subject Code |

Name of Subject |

Name of Book |

Name of Refernce Book |

|

1 |

MAT 202 |

PROBABILITY, STATISTICS AND NUMERICAL METHODS |

Jay L.Devore ,Probability and Statistics for Engineeringand sciences,8th edition cengage 2012,Ervin Kreyszig,Advanced EngineeringMathematics 10th Rdition JohnWily &sons 2016 |

|

|

2 |

MET202 |

ENGINEERING THERMODYNAMICS |

P. K. Nag, Engineering Thermodynamics, McGraw Hill, 2013 |

Moran J., Shapiro N. M., Fundamentals of Engineering Thermodynamics, Wiley, 2006 |

|

3 |

MET204 |

MANUFACTURING PROCESS |

1. Serope Kalpakjian, Steven R. Schmid - Manufacturing Engineering and Technology, Pearson |

1.Rao P.N., Manufacturing Technology, Volume -1, Tata McGraw Hill |

|

4 |

MET206 |

FLUID MACHINERY |

Bansal R. K., A Textbook of Fluid Mechanics and Hydraulic Machines, Laxmi Publications, 2010. |

Subramanya, K., Hydraulic Machines, Tata McGraw Hill, 1st edition, 2017 |

|

5 |

HUT 200 |

PROFESSIONAL ETHICS |

R S Naagarazan, A text book on professional ethics and human values, New age international (P) limited ,New Delhi,2006. |

Charles D Fleddermann, Engineering Ethics, Pearson Education/ Prentice Hall of India, New Jersey,2004. |

|

6 |

MCN 202 |

CONSTITUTION OF INDIA |

1 D D Basu, Introduction to the constitution of India, Lexis Nexis, New Delhi, 24e, 2019 |

1 Ministry of law and justice, The constitution of India, Govt of India, New Delhi, 2019. |

|

2 PM Bhakshi, The constitution of India, Universal Law, 14e, 2017 |

2 JN Pandey, The constitutional law of India, Central Law agency, Allahabad, 51e, 2019 |

SEMESTER 5 (KTU 2019 Scheme)

|

Sl. No |

Subject Code |

Name of Subject |

Name of Book |

Name of Reference Book |

|

1 |

ME 301 |

Mechanics of Machinery |

1. R S Khurmi and JK Guptha Theory of Machines ,S CHAND Publications. |

1. J. E. Shigley, J. J. Uicker, Theory of Machines and Mechanisms, McGraw Hill,2010, |

|

2 |

ME 303 |

Machine Tools and Digital Manufacturing |

Hajra Choudary, Elements of workshop technology, Vol I & II, Media Publishers, |

HMT, Production Technology, Tata McGraw-Hill,2001 |

|

3 |

ME 305 |

Computer Programming |

Computer Progtamming Amd Numerical methods jose |

Object Oriented Programming Balagurusamy |

|

Numerical Methods |

Gerald C. F. and P. O. Wheatley, Applied Numerical Analysis, Pearson,2004. |

Balagurusamy, Numerical Methods 1e McGraw Hill Education, 1999 |

||

|

4 |

EE 311 |

Electrical Derives and Controls for Automation |

Kothari DP and IJ Nagarath , Electric Machines |

M.D.Singh, K. B. Kanchandhani, Power Electronics, Tata McGraw-Hill,1998 |

|

5 |

HS 300 |

Principles of Management |

Harold koontz & Heinz Weihrich, Essentials of management, Mcgraw hill companies, 10th edition |

1. Principle of Management, Dr S Ramachandran, R Parameshwari, Dr. G Bhuvaneshwari, Air walk publication |

|

6 |

ME 367 |

Non Destructive Testing |

Non Destructive Testing, Airwalk Publications |

|

|

7 |

ME 371 |

Nuclear Engineering |

Nuclear Reactor Engineering, Dr.G Vaidyanathan |

S. Glasstone and A. Sesonske, Nuclear Reactor Engineering, D. Van Nostrand Company, INC. 1967. |

SEMESTER 6 (KTU 2019 Scheme)

|

Sl. No |

Subject Code |

Name of Subject |

Name of Book |

Name of Reference Book |

|

1 |

ME302 |

Heat and Mass Transfer |

1.Sachdeva R C, Fundamentals of Engineering Heat and Mass Transfer, New Age Science Limited, 2009 |

1.Holman J P, Heat Transfer, McGraw Hill, 2011 |

|

2 |

ME304 |

Dynamics of Machinery |

1. R S Khurmi and JK Guptha Theory of Machines ,S CHAND Publications. |

1. S. S. Rattan, Theory of Machines, Tata McGraw Hill, 2009. |

|

3 |

ME306 |

Advanced Machine Tools |

1.Advanced manufacturing Technology, S JOSE. |

1. M.P. Groover, E.M. Zimmers, Jr.CAD/CAM; Computer Aided Design and Manufacturing, Prentice Hall of India, 1987 |

|

4 |

ME308 |

Computer Aided Design |

1.Computer Aided Design and Analysis, Dr. S.Ramachandran,Airwalk publications, |

1. M.P. Groover, E.M. Zimmers, Jr.CAD/CAM; Computer Aided Design and Manufacturing, Prentice Hall of India, 1987 |

|

5 |

ME312 |

Metrology and Instrumentation |

Engineering Metrology and Instrumentation, RK Rajput, KATSON Books |

1. Anand K Bewoor, Vinay A Kulkarni, Metrology & Measurement, McGraw-Hill, 2009 |

|

6 |

ME368 |

Marketting Management |

Ramaswamy V.S. & Namkumari S, Marketing Management: Planning, Implementation |

Kotler P, Marketing Management: Analysis, Planning, Implementation and Control, |

|

7 |

ME376 |

Maintenance Engineering |

Maintenance engineering ,lakshmi publications,Dr G K Vijayaraghavan and Dr.S Sundaravalli |

Venkataraman, Maintenance Engineering and Management, Prentic-Hall of India Pvt. Ltd., |

SEMESTER 7 (KTU 2019 Scheme)

|

Sl. No |

Subject Code |

Name of Subject |

Name of Text Book |

Name of Reference Book |

|

1 |

ME401 |

DESIGN OF MACHINE ELEMENTS - I |

Jalaludeen , Machine Dsign, Anuradha Publications |

1. V.B.Bhandari, Design of Machine elements, McGraw Hill. |

|

2 |

ME403 |

ADVANCED ENERGY ENGINEERING |

Godfrey Boyle, Renewable Energy : Power for a Sustainable Future, Oxford University Press, |

Jefferson W Tester et.al., Sustainable Energy: Choosing Among Options, PH. |

|

3 |

ME405 |

REFRIGERATION AND AIR CONDITIONING |

Arora C. P, Refrigeration and Air-Conditioning, McGraw-Hill |

Stoecker W.F, Refrigeration and Air-Conditioning, McGraw-Hill Publishing Company |

|

4 |

ME497 |

MECHATRONICS |

Ramachandran K. P., G. K. Vijayaraghavan, M. S. Balasundaram, |

David G. Aldatore, Michael B. Histand, Introduction to Mechatronics and Measurement Systems, |

|

5 |

ME409 |

COMPRESSIBLE FLUID FLOW |

.Balachandran P., Gas Tables, Prentice-Hall of India Pvt. Limited |

Yahya S. M., Gas Tables, New Age International |

|

6 |

ME463 |

AUTOMOBILE ENGINEERING |

Automobile Engineering VOL.1 & 2, Dr.Kirpal Singh |

Heinz Heisler, Advanced vehicle technology, Society of Automotive Engineers |

SEMESTER 8 (KTU 2019 Scheme)

|

Sl. No |

Subject Code |

Name of Subject |

Name of Book |

Name of Reference Book |

|

|

ME401 |

DESIGN OF MACHINE ELEMENTS - II |

Jalaludeen , Machine Dsign, Anuradha Publications |

1. V.B.Bhandari, Design of Machine elements, McGraw Hill. |

|

|

ME404 |

INDUSTRIAL ENGINEERING |

B. Kumar, Industrial Engineering Khanna Publishers |

M Mahajan, Industrial Engineering & Production Management, Dhanpat Rai, |

|

|

ME476 |

MATERIAL HANDLING & FACILITIES PLANNING |

A W Peymberton, Plant layout and Material Handling, John Wiley |

James A Apple, Plant layout and Material Handlin, Krieger Pub Co |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

MA482 |

APPLIED LINEAR ALGEBRA |

Gilbert Strang Linear Algebra and its Applications 4th edition,Cengage learning 2006,Stephan Boyed , |

|

|

|

CE488 |

DISASTER MANAGEMENT |

Andrew, S., “Environmental Modeling with GIS and Remote Sensing”, John Willey and sons |

Ariyabandu, M. and Sahni P. (Eds), “Disaster Risk Reduction in South Asia”, Prentice-Hall (India), |

Other Links

- B.Tech. Aeronautical Engineering

- B.Tech. Civil Engineering

- B.Tech. Computer Science and Engineering

- B.Tech. Electronics and Communication Engineering

- B.Tech. Mechanical Engineering

- M.Tech. Applied Electronics And Communication Systems

- M.Tech. Communication Engineering and Signal Processing

- MBA

- Agriculture Engineering

- Computer Science & Engineering (Cyber Security)

- Computer Science & Engineering (Data Science)

Contact Us

Hotline +91 9605 771 555, +91 7510 331 777

Landline 0466-2344800

Copyright © 2023 | All Rights Reserved.